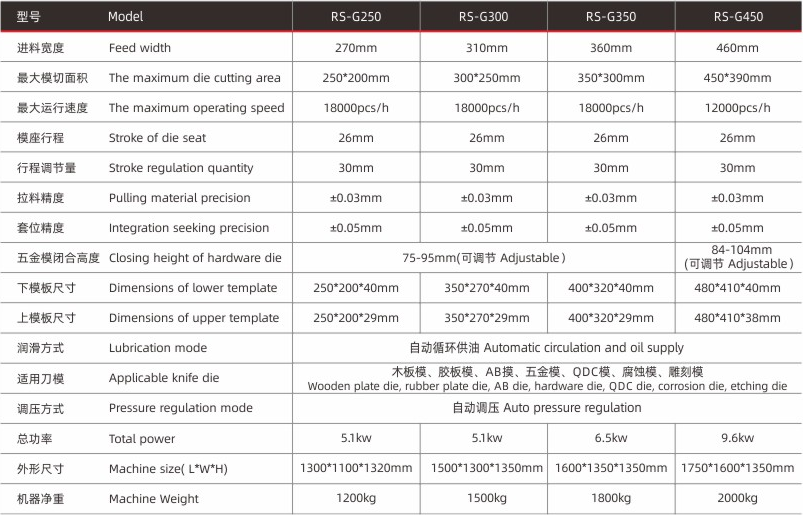

RS-G High-precision Die Cutting Machine

1. Fast die cutting,The maximum die cutting speed is 18,000 times/h.

2. Precision and convenient electric pressure regulation,It can increase commissioning efficiency greatly.

3. Feed rack uses tuning device for more convenient regulation.

4. The entire machine is protected by light curtain of mirror

surface. It can realize multi-surface protection for more safe and reliable machine operation.

5. It can realize automatic integrated blanking for many times easily. The maximum integrated blanking precision reaches ±0.03mm.

6. Standardize hardware die and installation so that it can be used for hardware die of other die cutting standards.

7. It supplies oil automatically with low noise of the entire machine. It can be used by any combination of gluing machine and splicer.

1. Fast die cutting,The maximum die cutting speed is 18,000 times/h.

2. Precision and convenient electric pressure regulation,It can increase commissioning efficiency greatly.

3. Feed rack uses tuning device for more convenient regulation.

4. The entire machine is protected by light curtain of mirror

surface. It can realize multi-surface protection for more safe and reliable machine operation.

5. It can realize automatic integrated blanking for many times easily. The maximum integrated blanking precision reaches ±0.03mm.

6. Standardize hardware die and installation so that it can be used for hardware die of other die cutting standards.

7. It supplies oil automatically with low noise of the entire machine. It can be used by any combination of gluing machine and splicer.